Injection Mold Manufacturers

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for Injection Mold,Injection molding machine,Production Injection Molding Machine,Basket Injection Molding Machine,Bucket Injection Molding Machine, We wholeheartedly welcome consumers all over the entire world appear to go to our manufacturing unit and have a win-win cooperation with us!

Injection Mold, Our skilled engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and items. For anyone who is thinking about our company and merchandise, remember to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We are going to always welcome guests from all over the world to our business to build company relations with us. Remember to feel free to get in touch with us for business and we believe we've been going to share the top trading practical experience with all our merchants.

Hot Products

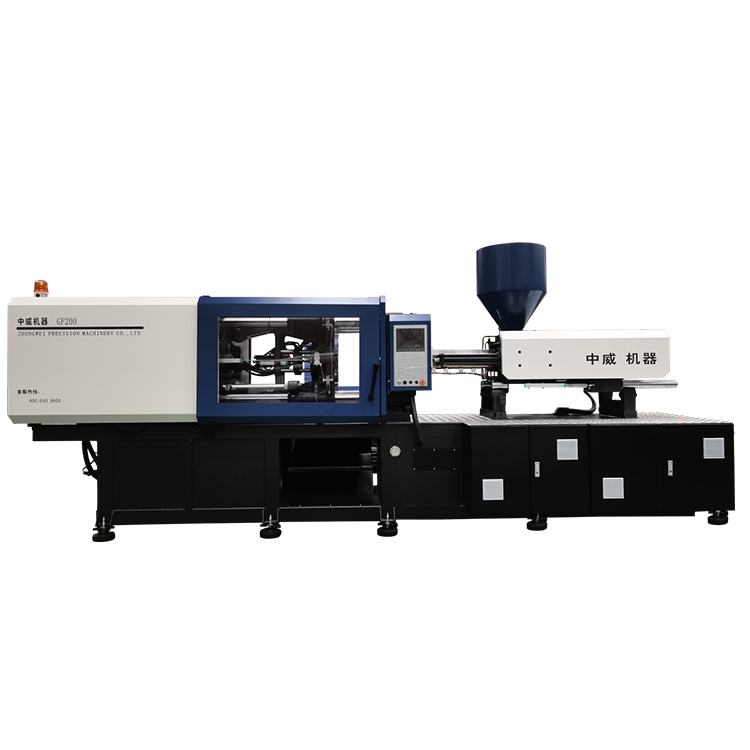

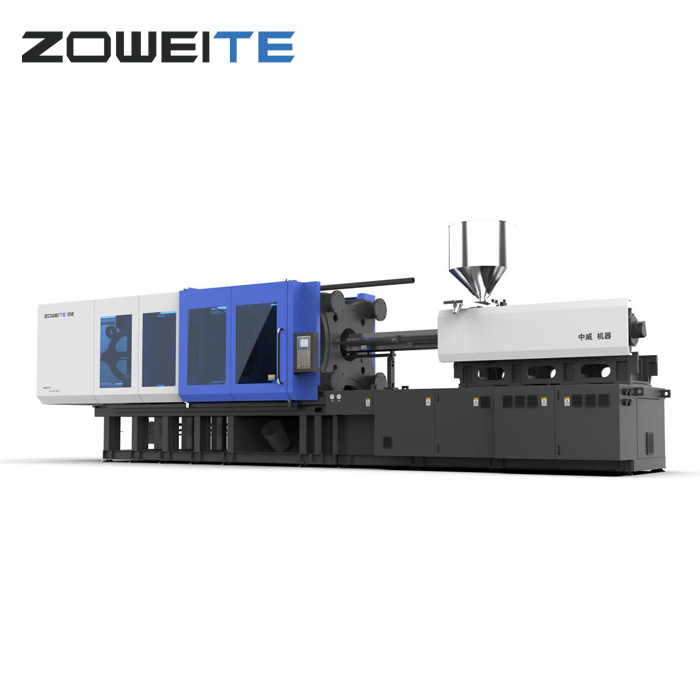

Fully Automatic 780 Tons Injection Molding Machine

The GIT® Fully Automatic 780 Tons Injection Molding Machine made in China is the molding equipment that makes thermoplastic or thermosetting plastics into various kinds of plastic products with plastic molding molds. The injection molding machine heats the plastic and applies high pressure to the molten plastic to make it shoot out and fill the mold cavity.Plastic Bucket Injection Molding Machine

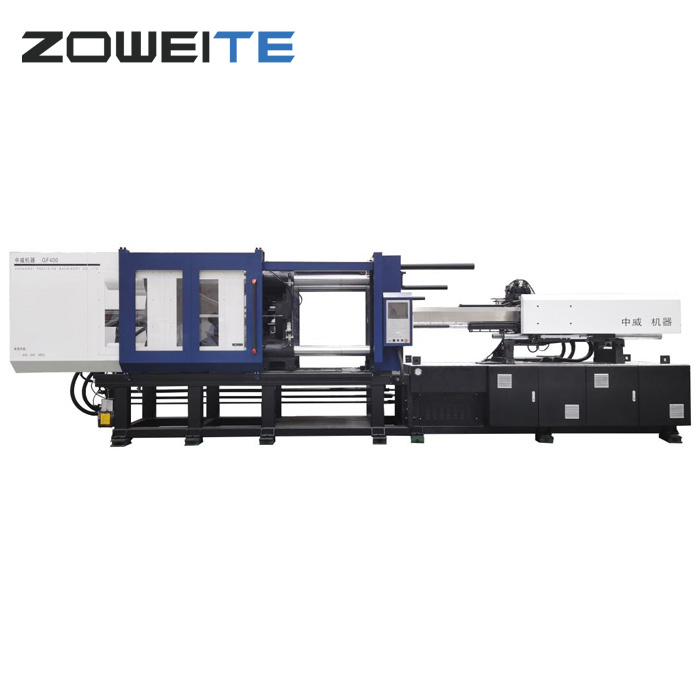

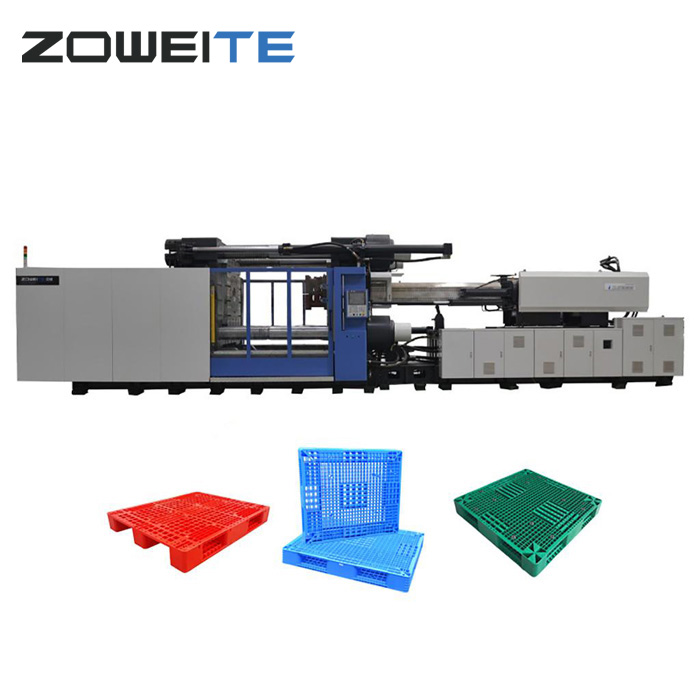

The manufacture of all plastic containers involves injection molding machine. Many buckets are made out of high-density polyethylene. HDPE is a durable, non-reactive thermoplastic that resists impact and inhospitable climates during transit or storage. In the GIT® plastic bucket injection molding machine process, raw HDPE resin, which in the beginning of the molding process is called stock, is loaded into a hopper. The hopper then directs the stock into a conveyance channel where a large screw forces the stock toward a mold. As the screw turns, the combination of friction and pressure heats the stock.1500 Ton Injection Molding Machine

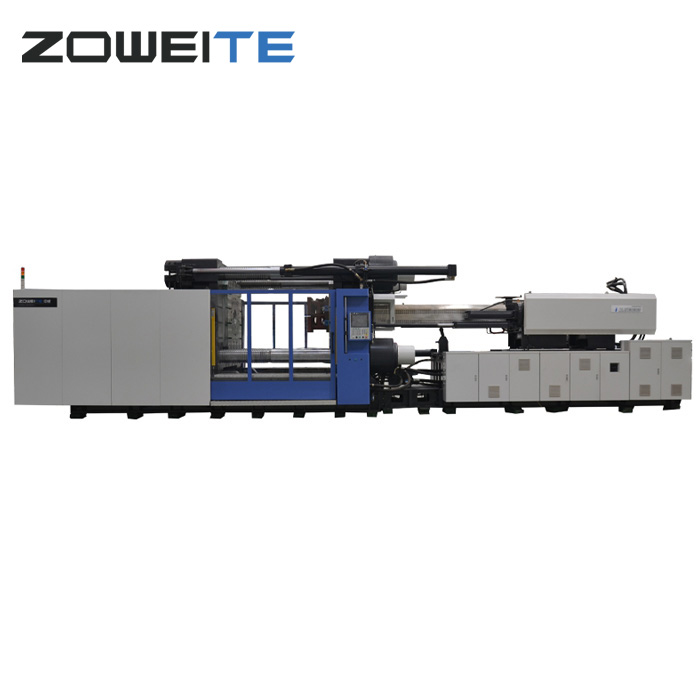

The GIT® 1500 ton injection molding machine made in China is a large-scale machine in the injection molding machine industry. The 1500 ton injection molding machine is also a special injection molding machine for environmental protection, medical, and household trash cans. It can be used to produce a 120L trash can.Food Container Injection Molding Machine

GIT® Food Container Injection Molding Machine is thin-walled food packaging, which requires extremely high injection speed. Ordinary injection molding machine can not meet the requirements of thin-walled food container, because the injection molding pressure of ordinary injection molding machine is small and slow speed.It works similar to a syringe for injection by using the thrust of the screw into the closed mold cavity and curing the product. Our offered machine is developed with supreme grade raw materials and latest technology in compliance with set industry standards and to ensure its high quality and durability. Moreover, it is extensively used in various molding applications.Plastic Bucket Injection Molding Machines

GIT® is manufacturer and supplier for providing customers with bucket injection turnkey engineering. If you are planning to invest in new projects of Plastic Bucket Injection Molding Machines and injection mold. Then please contact us.Car Bumper Injection Molding Machine

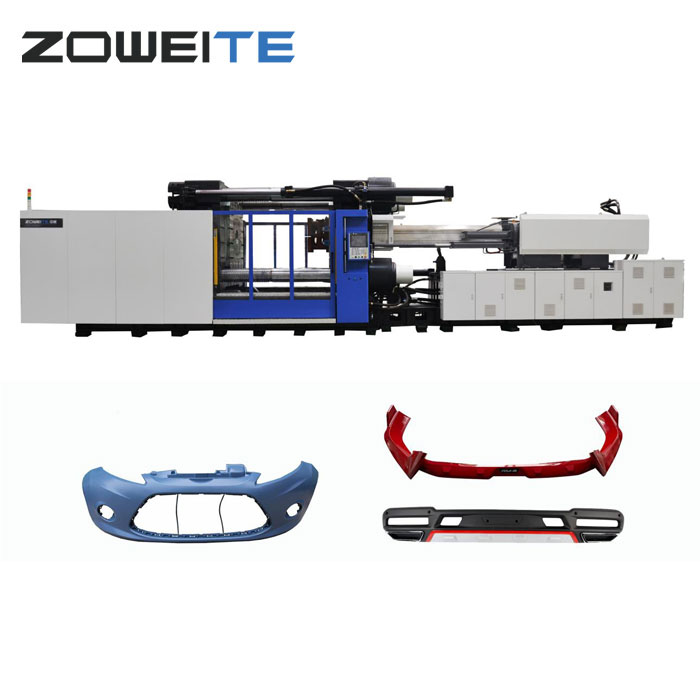

With the rapid development of automobile industry, plastic parts are more and more widely used in automobiles. The application of automobile plastic parts has significant effects on reducing automobile quality, saving fuel, promoting environmental protection and recyclability. Car Bumper Injection Molding Machine bumper mainly adopts injection molding. GIT® GF2300LB machine is specially designed for bumper.