Low failure rate 320 tons injection molding machine Manufacturers

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Low failure rate 320 tons injection molding machine,High-speed 320 tons injection molding machine,High Response Hybrid Servo System 320 tons injection molding machine,Rigid support structure320 tons injection molding machine,Food container320 tons injection molding machine, We look forward to providing you with our goods while in the in close proximity to long term, and you will discover our quotation is extremely realistic as well as high-quality of our solutions is incredibly outstanding!

Low failure rate 320 tons injection molding machine, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

Hot Products

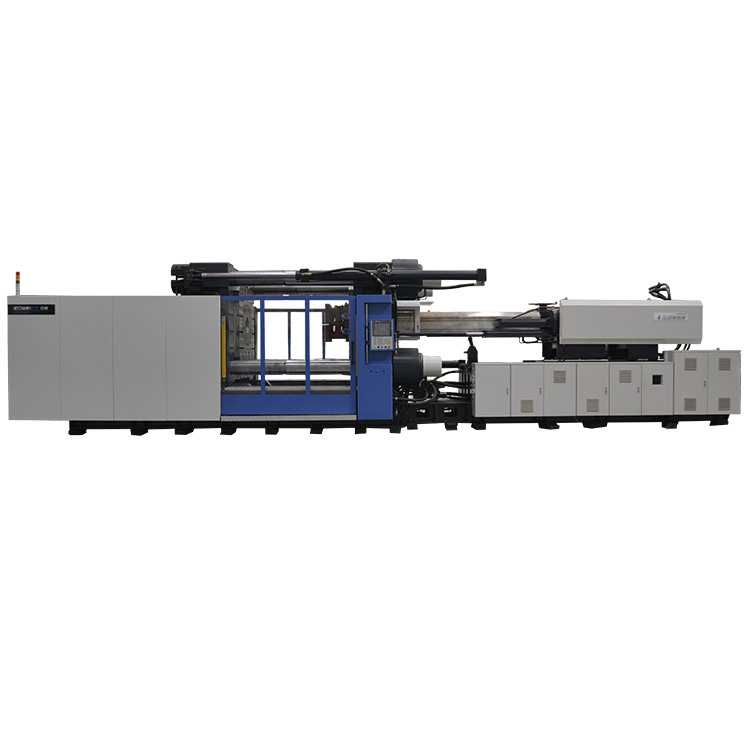

Two Plate Injection Molding Machine

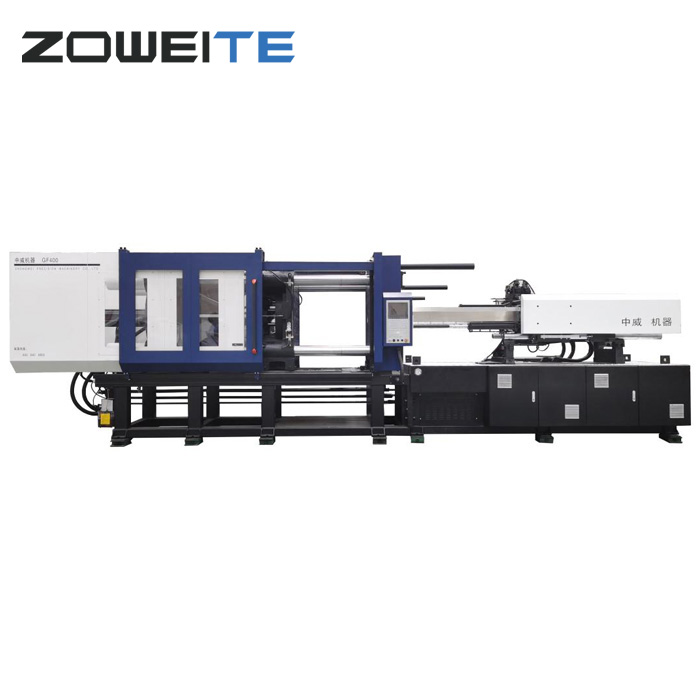

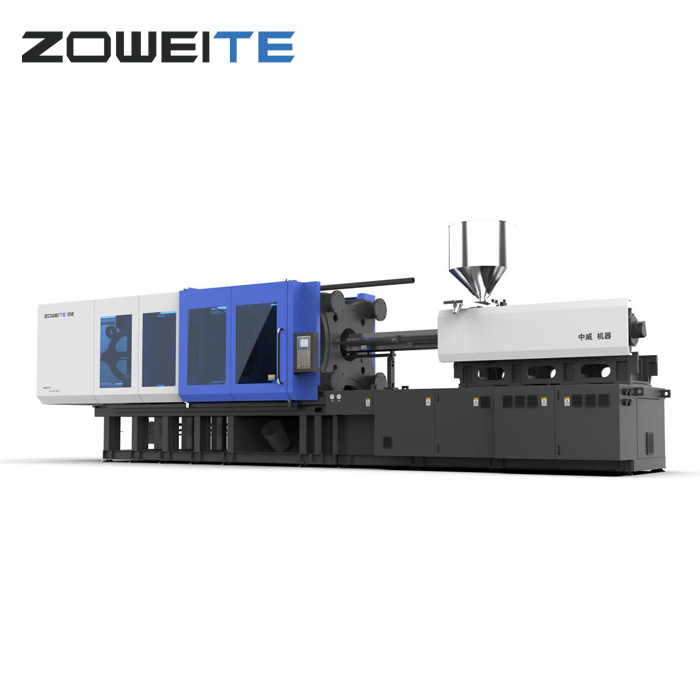

GIT® Injection molding machine is also known as injection machine or molding machine. It is the main making thermoplastic or thermosetting plastics into plastic products of various shapes with plastic molds. The injection molding machine applies high pressure to the molten plastic to make it shoot out and fill the mold. According to the different number of mold plates of the injection molding machine, the injection molding machine is divided into two plate injection molding machine and three plate injection molding machine. The two plate injection molding machine is simply an injection molding machine with two mold plates. In addition, the two plate injection molding machine is mainly hydraulic mold locking.Fruit and Vegetable Basket Injection Molding Machine

The Fruit and Vegetable Basket Injection Molding Machine is a special model of disposable plastic fruit basket production equipment developed by our company according to the characteristics of the fruit and vegetable basket.GIT® GF400K, GF530K and other injection molding machine are specially developed by GIT® for fruit and vegetable basket.Paint Bucket Injection Molding Machine

Paint bucket injection molding machines are widely used in the manufacturing industry for producing paint containers and offer advantages like high production rates, precision, and the ability to produce large quantities of uniform and consistent paint buckets.Nylon Tie injection moulding machine

GIT® Nylon tie injection moulding machine is produce various sizes nylon tie required in the market . Usually we recommend our GF200ton injection molding machine. It is special machine for produce nylon tie. GIT® is nylon tie injection moulding machine manufacturer and supplier in China.310 tons injection molding machine

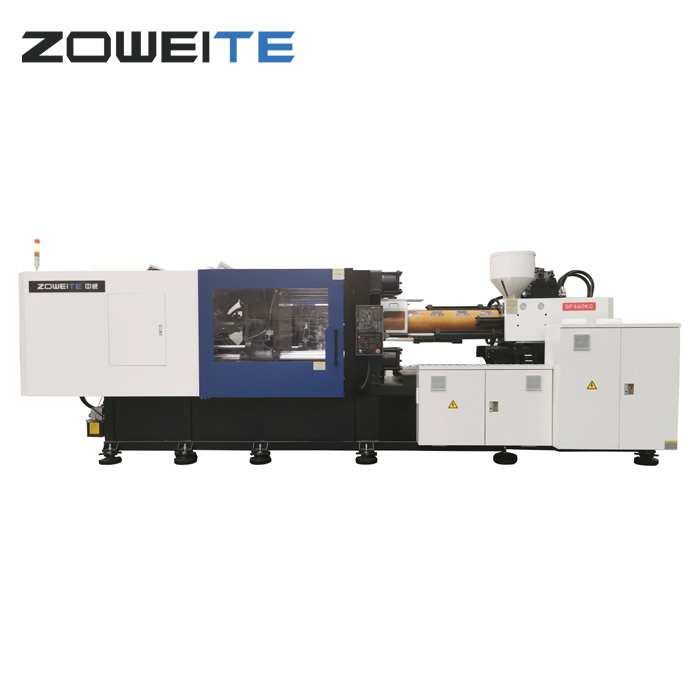

The GIT® 310 tons injection molding machine is a high speed, servo injection molding machine. Its high response oil-electric servo system cooperates with slide rail to project a rigid support structure. The unique stable high pressure and high speed injection system of high speed injection molding machine is suitable for molding broader products, such as thin walled food containers, plastic cups, flower pots and other thin walled packing products. 310tons has high quality, stable operation, low failure rate, easy maintenance and repair.Fully Automatic 780 Tons Injection Molding Machine

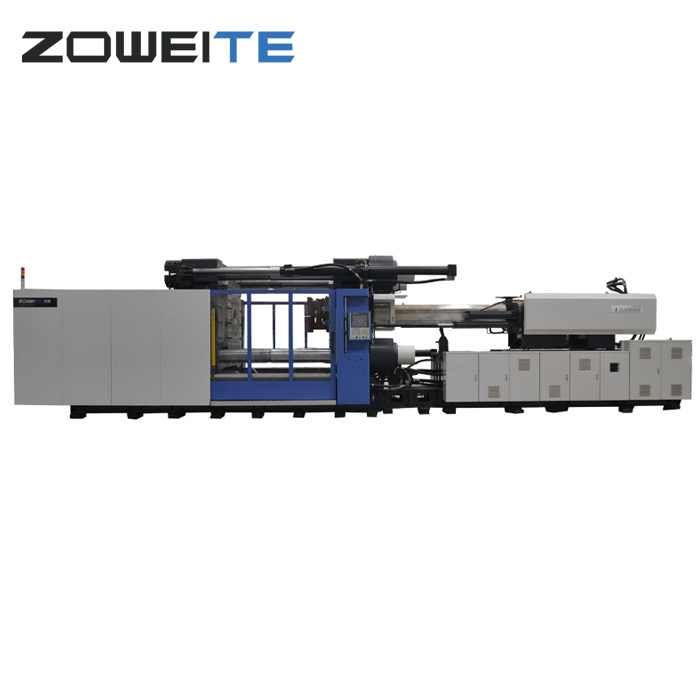

The GIT® Fully Automatic 780 Tons Injection Molding Machine made in China is the molding equipment that makes thermoplastic or thermosetting plastics into various kinds of plastic products with plastic molding molds. The injection molding machine heats the plastic and applies high pressure to the molten plastic to make it shoot out and fill the mold cavity.