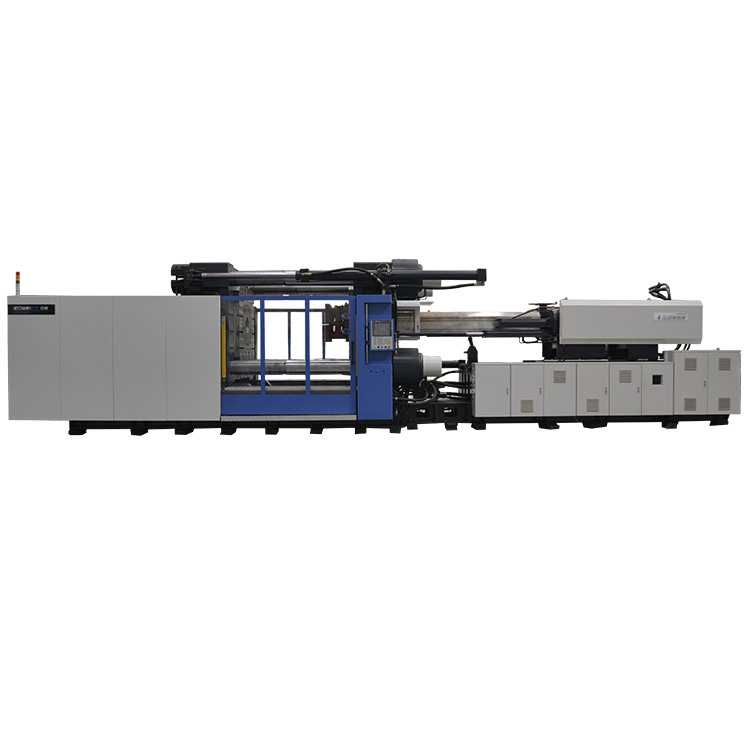

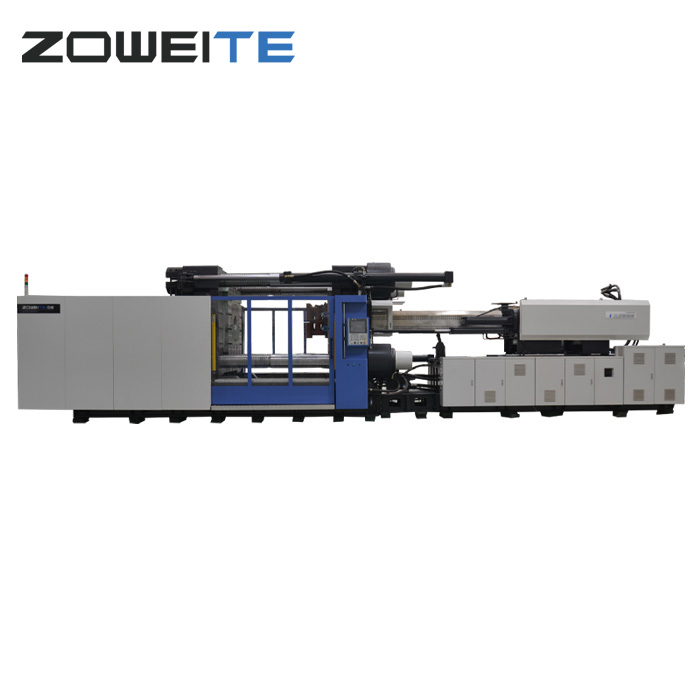

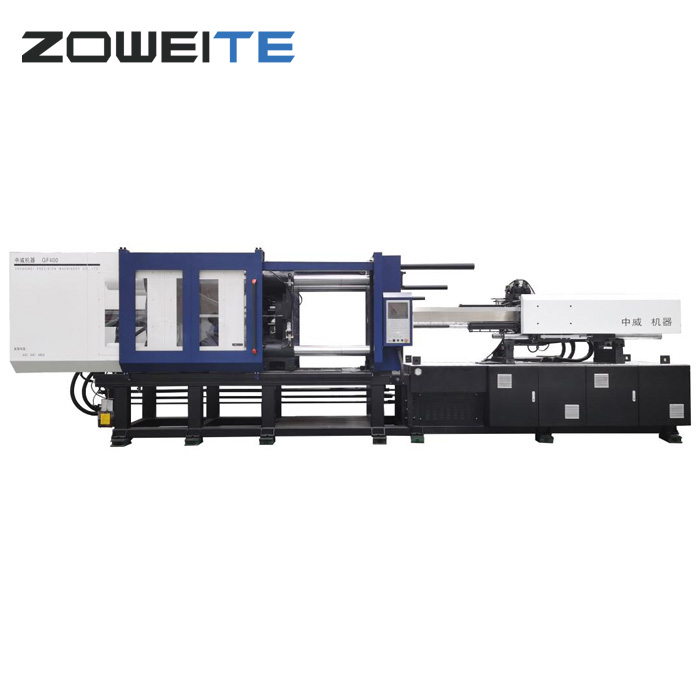

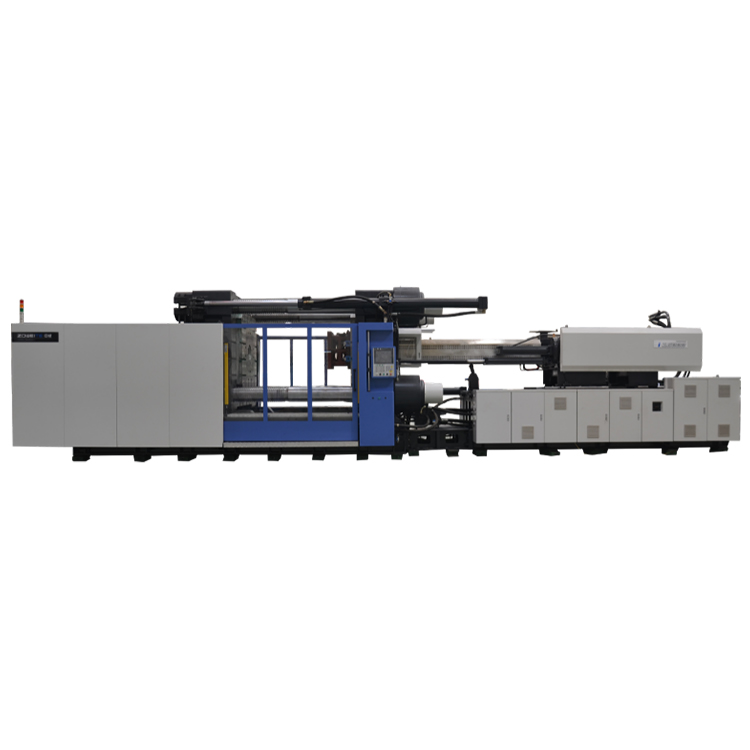

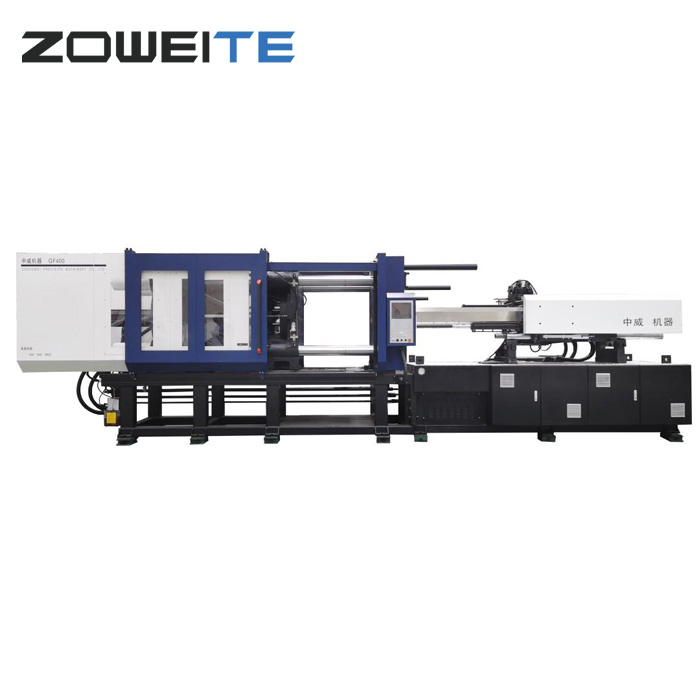

Auto bumper injection molding machine Manufacturers

To frequently enhance the administration program by virtue on the rule of "sincerely, very good faith and high-quality are the base of enterprise development", we widely absorb the essence of related products internationally, and consistently develop new products to fulfill the calls for of customers for Auto bumper injection molding machine,Auto bumper injection machine,1500 tons Auto bumper injection molding machine,2300 tons Auto bumper injection molding machine,Easy maintenance Auto bumper injection molding machine, With our rules of " organization track record, partner trust and mutual benefit", welcome all of you to function together , improve jointly.

Auto bumper injection molding machine, Upon today, now we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to offer the highest quality solutions with best price. We are looking forward to doing business with you!

Hot Products

Plastic Crate Injection Molding Machine

Plastic crates are manufactured through a process called plastic injection molding. An GIT® plastic crate injection molding machine mold made in China is a machine that takes raw plastic product, or stock, and processes it into a usable product. plastic crate injection molding machine molders begin with a collection of stock in a hopper which is directed into a conveyance channel. A screw will turn in the conveyance channel which combined with heating, helps to liquefy the plastic in preparation for the mold.High Speed Household Products Machine

ZOWEIE® supplier's High Speed Household Products Machine adopts an advanced control system that can accurately control injection parameters such as pressure, speed and temperature.Servo Energy Saving Injection Molding Machine

Energy conservation and environmental protection are the mainstream of modern industrial development. GIT® injection molding machine company focuses on the new servo energy saving technology of injection molding machine. The servo energy saving injection molding machine has realized the excellent characteristics of high energy, high precision, high response, low noise, low oil temperature. It can be widely used in the injection molding of plastic carts such as auto parts, industrial dustbin, plastic crate and larger plastic pallet.650 Ton Injection Molding Machine

GIT® Injection molding machine is a kind of main molding equipment that uses thermoplatic or thermosetting materials to make plastic products of various shapes with plastic molding molds. The injection molding machine is usually composed of injection system, clamping system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc. GIT 650 ton injection molding machine is a special injection molding machine for plastic bucket, which is suitable for injection molding machine of barrel products for lubricating oil bucket, paint bucket, chemical fertilizer bucket, and other purposes. GIT 650 ton injection molding machine also has standard machines. We can recommend the suitable machines according customers’ requirements.Pet Preform Manufacturing Machine

Modern Injection molding machine has the characteristics of complex products, less processing and more plastic types. In the rise of the plastic industry today, the development of PET preform manufacturing machine made in China is very rapid. The special PET preform manufacturing machine developed by GIT® is equipped with a special screw, with the characteristics of stable high speed plasticity, suitable for mineral water PET preform, beverage PET preform, oil pot PET preform etc.120 tons injection molding machine

GIT® 120 tons injection molding machine is a small injection molding machine with small floor area. It is suitable for producing all kinds of small plastic parts, such as plastic caps, nylon cable ties, etc. GIT® 120 tons injection molding machine has servo machine and standard injection molding machine. GIT manufacturer can also provide the suitable machine and best offer according client’s requirements.