The Comprehensive Guide to Finding Top Quality Suppliers in Best China for Your Business Needs

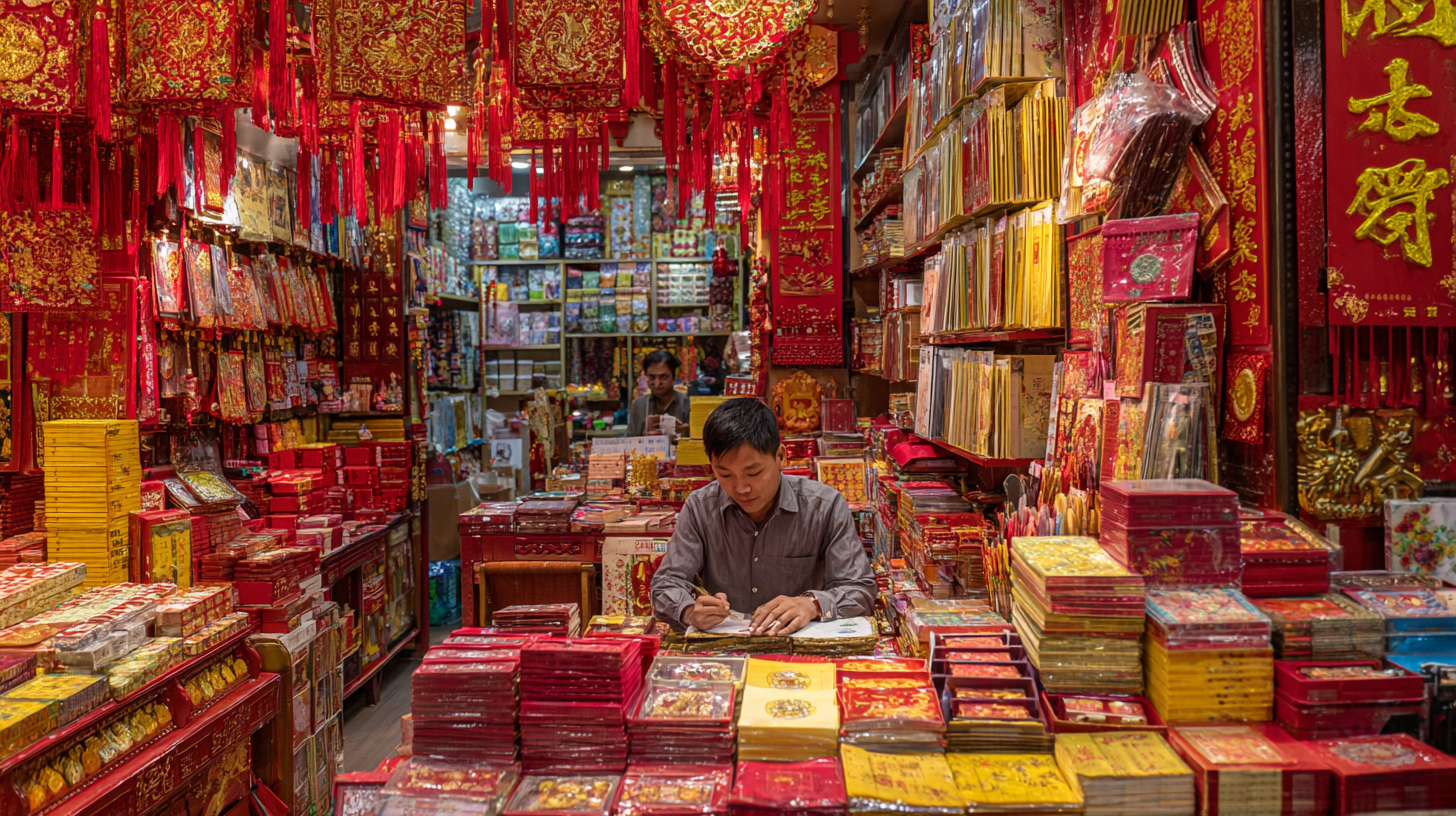

In the realm of global commerce, sourcing quality suppliers has never been more crucial for businesses aiming for success. As the manufacturing powerhouse of the world, China stands out with its unparalleled ability to produce a diverse array of goods at competitive prices. This comprehensive guide will navigate you through the intricate process of identifying top-quality suppliers in China, ensuring that your business needs are met with excellence. With the motto "World-Class Manufacturing, China's Pride, Exporting Globally" in mind, we will explore strategies for evaluating potential partners, understanding industry standards, and leveraging China's vast market to elevate your business. Whether you’re a startup looking to scale or an established enterprise seeking reliable production, this guide is your essential resource for tapping into China's manufacturing prowess.

Understanding the Unique Features of Different Product Categories in China

When navigating the vast landscape of suppliers in China, it is essential to recognize the unique features of different product categories. Each category possesses distinct characteristics that can significantly influence sourcing decisions. For instance, electronics manufacturing in China is renowned for its cutting-edge technology and rapid production capabilities. This sector often benefits from stringent quality control measures and an extensive network of parts suppliers, making it an attractive choice for businesses looking for innovation and speed.

On the other hand, the textile and apparel industry showcases China's prowess in design and craftsmanship. With a rich tradition in textiles, suppliers in this category often emphasize quality materials and intricate production techniques. Understanding the nuances of fabric sourcing, compliance with international standards, and the importance of ethical manufacturing practices is crucial for businesses aiming to build a reputable brand in the fashion space. By tapping into these unique features of various product categories, companies can tailor their supplier searches to align with their specific business needs and ensure they partner with the right manufacturers for optimal results.

Identifying the Right Suppliers for Your Specific Business Needs

Finding the right suppliers is a pivotal step for any business looking to thrive in a competitive market. In China, a country known for its vast manufacturing capabilities, identifying suppliers that align with your specific business needs can seem daunting. Begin by clarifying your requirements: the type of products you need, desired quality standards, and budget constraints. This clarity will guide your supplier search, filtering out those who do not meet your precise criteria.

Once you have a clear understanding of your needs, employ strategic approaches to identify potential suppliers. Utilize online platforms that specialize in Chinese manufacturers, such as Alibaba or Made-in-China, to browse through ratings and reviews. Attend trade shows and industry expos to meet suppliers in person and assess their offerings firsthand. Don’t hesitate to request samples to evaluate product quality, and engage in direct communication to discuss your requirements in detail. This process will not only help you to gauge the capabilities of potential suppliers but also foster relationships that can benefit your business in the long run.

Evaluating Supplier Credentials and Quality Assurance Practices

In today’s competitive market, evaluating supplier credentials is essential for ensuring the sustainability and quality of your supply chain. When it comes to selecting suppliers in China, businesses must rigorously assess their qualifications, including certifications, production capabilities, and track records. A thorough vetting process not only mitigates risk but also enhances the overall quality of the products and services offered. Utilizing third-party audits and industry-specific evaluations can provide deeper insights into a supplier’s operational standards and commitment to quality assurance practices.

Moreover, companies aiming to foster a sustainable value chain should focus on suppliers who prioritize environmental, social, and governance (ESG) factors. With two-thirds of a company's ESG footprint stemming from its suppliers, integrating sustainability criteria into the supplier selection process is crucial. This includes examining a supplier's carbon emissions, labor practices, and community engagement. By choosing suppliers that align with sustainability goals, businesses can not only improve their own ESG performance but also contribute to a more responsible global supply chain.

Effective Communication Strategies with Chinese Suppliers

Effective communication is crucial when working with Chinese suppliers to ensure a smooth and productive business relationship. One of the first steps in establishing effective communication is to understand the cultural nuances that influence how business is conducted in China. Chinese culture places a strong emphasis on respect, formality, and building relationships, known as “guanxi.” Therefore, it’s important to approach initial communications with a polite tone and a clear introduction of your business and intentions.

Utilizing technology can significantly enhance your communication strategies. Platforms like WeChat or Alibaba's messaging system are popular among Chinese suppliers and can facilitate quick exchanges. Ensure that your messages are concise and straightforward, as language barriers may complicate complex discussions. Providing clear specifications, detailed inquiries, and timely feedback will show your suppliers that you value their services, fostering a positive rapport that can lead to better negotiation outcomes and quality products.

Navigating Shipping, Import Regulations, and Logistics for Your Products

Navigating the intricate landscape of shipping, import regulations, and logistics is critical for businesses sourcing products from China. As global supply chains evolve, understanding the myriad of regulations that govern international trade is essential. For instance, new rules like the EU's Carbon Border Adjustment Mechanism (CBAM) are reshaping how companies approach their logistics strategies, necessitating a deeper awareness of both environmental standards and compliance.

In addition to understanding large-scale regulations, businesses must also keep abreast of local changes such as the recent VAT collection updates in Thailand, impacting imports valued between 1-1500 baht. Staying informed about these financial aspects ensures that companies avoid unexpected costs that can disrupt their supply chain. Moreover, familiarity with customs procedures is equally important; for example, shipping perishable goods or cosmetics may involve specific requirements that, if neglected, could lead to costly delays.

Businesses looking to thrive in the competitive global market should prioritize developing a robust understanding of logistics and import regulations tailored to their specific needs. By fostering this knowledge, companies can streamline their importing processes, minimize risks, and enhance overall operational efficiency.

The Comprehensive Guide to Finding Top Quality Suppliers in Best China for Your Business Needs

| Supplier Type | Location | Product Category | Shipping Options | Lead Time (Days) | Minimum Order Quantity |

|---|---|---|---|---|---|

| Manufacturer | Guangzhou | Electronics | Sea Freight, Air Freight | 30 | 100 units |

| Wholesaler | Shenzhen | Fashion Apparel | Express, Sea Freight | 15 | 200 units |

| Trading Company | Yiwu | Home Goods | Air Freight, Courier | 10 | 50 units |

| Manufacturer | Shanghai | Automotive Parts | Sea Freight, Rail Freight | 45 | 250 units |

| Distributer | Ningbo | Kitchenware | Express, Sea Freight | 20 | 100 units |